Consumer goods logistics

Industrisektor Consumer goods logistics

Overview

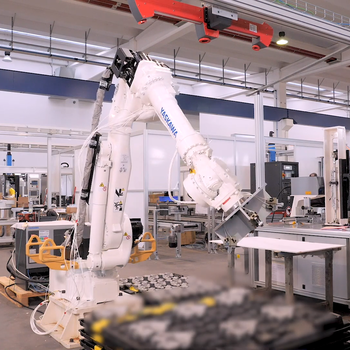

Motoman Robots in Fast Moving Consumer Good (FMCG) Logistics, Warehouses, Distribution Centers and E-Commerce

Motoman Robots are involved in all process steps along the value chain of production and distribution of Fast Moving Consumer Goods - food, beverages, pharmaceuticals, white goods, domestic use products, and electronic and industrial convenience products. Robots provide the right flexibility in this fast changing market - new product variants, new quantities and product bundles, new product promotion and distribution strategies - almost every day.

Packaging and Order Fulfilment

In the value chain of production, a lot of automated processes are established to manufacture parts, to pack, palletize them (Packaging Industry) and to store products in warehouse inventories as stock keeping units (SKUs). Robotic automation is well established in this production value stream.

In the value stream of distribution, those SKUs are taken out with the purpose to fulfil a customer's order, being selected, packed, palletized and consolidated into shipping carriers or containers. Order Fulfilment has a couple of unique process steps, which are executed by robots. In Order Fulfilment, we see a lot of large hard warehouse automation today, but the demand from small and medium size distribution centers, copackers or 3rd party logistic suppliers for flexible automation is high, leading to a rising demand of robots.

Motoman Robots working in the cold storage (stable low temperature environments)

To be honest - flexible robot cables, gear sealings, lubrication grease and electronic components are not really made for temperatures below 0 degrees. For those applications, the robot can be wrapped into a robot suit.

Order Fulfilment with Motoman Robots

Logistics is a wide field for Motoman Robots to be involved. Classical applications in Warehouses are "Pick&Pack" and "Palletizing". In addition to this, in warehouses we have the task of order fulfilment, coming along with typical Logistics tasks and methods for robots.

Piece Picking (Goods-to Picker) with Motoman Robots

Piece Picking is a growing application category in warehouses, due to the exciting breakthrough of machine vision technology. This technology addresses the typical warehouse requirement of having a high variety of SKUs to be picked. With classical Vision systems, every single part variant needs to be teached in upfront, which is a high organisational burden for commissioning. With AI (neural network based) part recognition software, after an initial upfront training phase where the software builds up its own decision criteria, parts can be picked which have never seen by the vision system before. In addition to the part recognition job, a good Robotic AI Vision software is identifying the optimum target position to pick, providing robot trajectories to approach and pick algorithms.

On the one hand, YASKAWA are supporting the exciting startup playfield in this technology all over the world, where the ideas and technology mock-ups are born. On the other hand, within our worldwide System Integrator network, you will find experienced System Integrators who are capable to turn your idea into a 24/7 stable and reliable application.

Large E-Commerce and FMCG Retailers count on Good-to-Picker principle in their warehouses - using a fleet of mobile platforms (without robotic arms), and moving shelves of goods or boxes on conveyors, in front of very versatile stationary robotic piece pickers.

In large automatic warehouse installation, we also find Robot Pickers located at the conveyor outlets of large warehouses. Robot Pickers are picking parts out and commissioning them into racks, cartons or boxes, to fulfil orders.

Piece Picking (Picker-to-Goods) with Motoman Robots

The Picker-to-Goods philosophy would send mobile robot pickers - equipped with robotic arms - through the shelve rows of the warehouse, picking pieces from the shelf and collecting them to fulfil an order. Although some pilots have been presented, almost no real robotic Single Piece Picker-to-Goods applications are out there. This is because of unpredictable product placement conditions of the products in the shelves, low achievable pick rates due to high portion of motion time, safety considerations in an environment with humans, demanding vision technology and WMS software interfacing requirements and - last but not least - high levels of discipline and automation understanding of the people working in the warehouses and stores. Technically spoken, Motoman Robot Technology would be ready to take over their part in this game (Collaborative HC10 and HC20 Cobots, which have a good reach and payload to put on a mobile platform, and Intelligent Vision Control) - let's see what the future brings....

Case Picking (Goods to Picker) with Motoman Robots

Case Picking is a growing application category in warehouses, based on classical Pick / Place / Palletizing Packaging Industry machinery, but supplemented by exciting machine vision technology.

Case Picking - Layer Palettizing with Motoman Robots

In larger distribution center installations, for the purpose of order fulfilment, large layer pickers are used.

E-Commerce Returns Management - Random Case Depalletizing

Robotic Random Case Palletizing is a way to deal with the problem of increasing return and exchange rates from E-commerce customers. In combination with integrated vision systems, Motoman Robots can manage many different SKUs.

Contract Packaging (Copackers) - 3rd Party Logistics

Contract packagers, or copackers, are companies who package consumer good products for their clients. Usually they receive deliveries from the manufacturers, unpack them, pack and relabel them into new package formats or seasonal promotion packs. Our experienced System Integrators provide flexible and modular, high throughput copacking lines with Motoman-Robots installed for case opening, unpacking and packing.